What Are The Strongest Metals?

When it comes to strength, not all metals are equal. While all metals can and will bend under enough force, some are stronger than others.

Metal strength can be categorized into several categories, including hardness, yield strength, and compressive strength.

Hardness

Hardness refers to the ability of a metal to resist being scratched or bent. It is usually indicated by a number on the Brinell scale (a high number suggests hardness), which can be improved via heat treatment. As you might assume, the "hardest" metals are the most difficult to deform. The hardest known metal is chromium. Chromium is a type of steel known as stainless steel — it has a high carbon content and must be supplemented with other metals to prevent corrosion.

Yield strength

This is a more specific type of hardness — the amount of stress a metal can withstand without becoming permanently deformed. It's usually expressed in KSI (thousands of pounds per square inch), and it has a massive role in determining a material's ultimate tensile strength.

The yield strength of a material is the stress at which plastic deformation occurs. Yield strength for metals is generally defined as 0.2% offset from the 0.2% proof stress. For example, if the 0.2% proof stress is 100 MPa, the yield strength would be 120 MPa.

Compressive strength

The amount of pressure required to deform a metal or cause it to fail through shearing or breaking. For example, carbon fiber has incredible compressive strength (used in things like bridge girders every day) but is far weaker when tensioned.

Tensile Strength

Tensile strength is another important property of materials that can be measured by conducting tensile tests on samples. A tensile test measures how much stretch occurs before failure occurs in a specimen that has been stretched by two forces pulling on it from opposite ends. This type of test gives us an idea of how well materials like metals will hold up when used for things like bridges, buildings, or other structures that need intense support beams to function correctly.

Tensile strength is the maximum stress a material can withstand while being stretched or pulled before breaking. Tensile strength is an essential indicator of a material's ability to perform in an application and often correlates to how strong the fabric feels when touched.

Elongation

Elongation refers to how much a material will stretch before breaking. It's an essential measurement for materials like wire or rope required to hold significant weights without breaking. It's also helpful in comparing materials to one another. For example, steel has low elongation, whereas nylon typically has very high extension since it's made from flexible molecules (polymers).

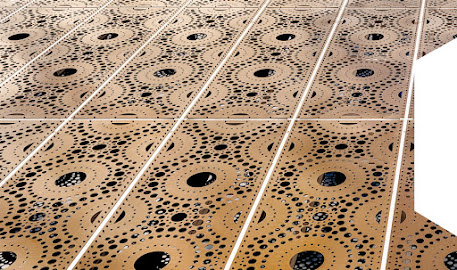

The Metrix range of architectural perforated metal products combines strength, precision, functionality, and design creativity. Select from over 120 standard patterns or work with our design consultants to create a unique project-specific way. The Metrix is your trusted supplier of architectural perforated metal products and systems.

We look forward to the opportunity of building new partnerships and meet new challenges in 2021. So, if you would like to talk about how Metrix Group® can assist in your next project, feel free to email one of our technical sales staff (sales@metrixgroup.com.au) or call us direct on 1300 792 493.

Comments

Post a Comment